Engineering Services

Engineering

Design for Manufacturability – DFM

Starting when the first drawings are presented to Electrol, our mechanical and electrical engineers are looking for ways to drive out waste from the process. Our engineers’ extensive knowledge of available wire/cable types and components help our customer obtain their cost and lead time requirements without reducing the product functionality or quality. Since 95 percent of manufacturing cost is set once the design is complete, Electrol can help you make component choices in the design phase to limit future warranty, service and cost issues. Technical data and samples are presented to the customer with each DFM suggestion. Electrol provides on-site engineering and assembly support at the customer’s location.

Starting when the first drawings are presented to Electrol, our mechanical and electrical engineers are looking for ways to drive out waste from the process. Our engineers’ extensive knowledge of available wire/cable types and components help our customer obtain their cost and lead time requirements without reducing the product functionality or quality. Since 95 percent of manufacturing cost is set once the design is complete, Electrol can help you make component choices in the design phase to limit future warranty, service and cost issues. Technical data and samples are presented to the customer with each DFM suggestion. Electrol provides on-site engineering and assembly support at the customer’s location.

Forward Engineering

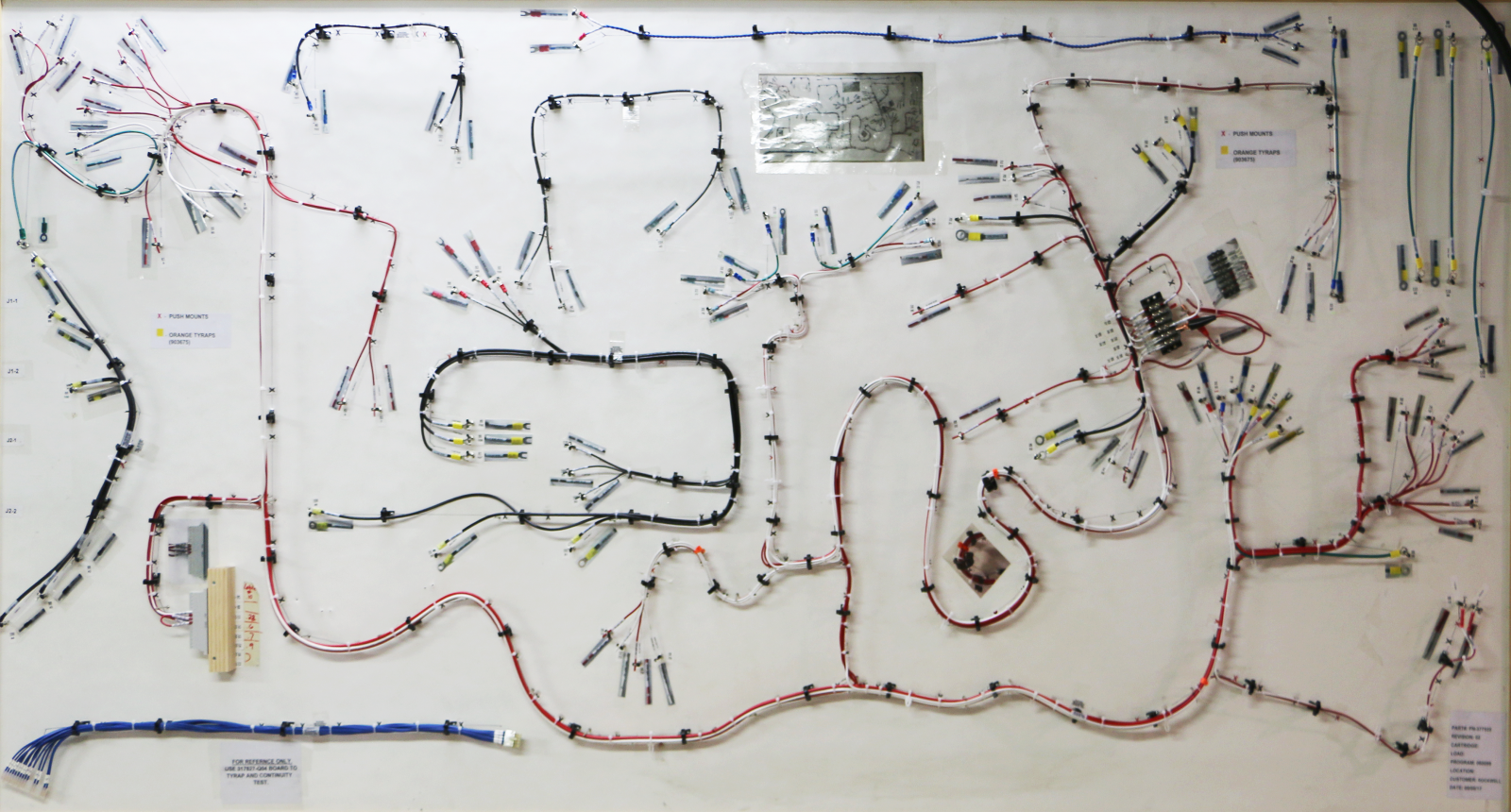

The specific requirements of each customer typically require a unique wire and cable assembly. Electrol’s engineers coordinate internal resources to each customer’s project and dedicate personnel responsible for building one-of-a-kind wire/cable prototypes quickly. Once the prototypes are approved by the customer, Electrol uses a systematic process to release the products into volume production.

Electrol utilizes engineering software formats including: AutoCAD, Pro-E and Solidworks.

Re-Engineering

Electrol engineers can quickly duplicate a product without the aid of drawings, documentation or computer model. Electrol can quickly assess the feasibility of re-engineering an existing product, ultimately saving customers time and effort. Electrol’s re-engineering process includes:

- Identifying the product’s components and their interrelationships

- Creating representations of the product in another form that reduces costs (both component and manufacturing techniques)

- Rapidly prototyping the new product design

- Customer determines the feasibility of the new product design and approves

- Drawings are created and the process detailed in forward engineering section is completed

Electrol’s ability to reverse engineer a design can sometimes greatly reduce the amount of time required to develop the perfect product configuration.

Inventory Management Programs

Electrol offers a variety of inventory management programs to mitigate risk of stock outs due to uncertainties in demand and to reduce lead times. Electrol can develop custom inventory programs to accomplish a customer’s specific needs, reducing customer costs, lead times and inventory levels. These inventory programs include:

- Raw material stocking programs located at Electrol or partner suppliers.

- Finish goods stocking programs located at Electrol or customers’ site.

- Kanban replenishment systems throughout the supply chain.

- Supplier managed inventory programs at a customer’s site, point-of-use delivery by an Electrol associate and auto replenishment via the Electrol web-based ordering system.